|

RdF Corporation’s history goes back to 1939. MIT Professors Arthur C. Ruge and Alfred V. deForest formed Ruge-deForest, Inc. to develop and market the bonded resistance wire strain gage invented by Professor Ruge in 1938. Similar surface resistance temperature sensors were also developed. The strain gage business was sold to BLH in 1955. The temperature measurement division relocated to Hudson, NH in 1959 and was renamed RdF Corporation. RdF is still a closely held corporation with stockholders involved in daily operations.

Design and Manufacturing:

RdF products have a reputation for ruggedness, quality and reliability gained from many years of experience in actual operational service. This reputation and the success of RdF temperature sensors is the result of our adherence to time proven design principles, our ability to work closely with our customers to assure compliance with specific operational requirements, and close attention to details in robust manufacturing processes.

Quality Assurance System:

RdF received ISO 9001 certification in March 1996, and ISO 9001-2000 certification in April 2002. Prior to ISO, the RdF quality system met the requirements of Mil-I-45208A. It also incorporated several customer specific supplements, some of which carried requirements to higher quality specifications. Other approvals are to specific NASA requirements and Federal Aviation Regulations, in particular FAR Part 21.303 for aircraft parts.

RdF sensors have been qualified on many military and aerospace programs to the environmental requirements of MIL-STD-810. Qualification testing to the requirements contained in RTCA DO-160 has also been done. Test and calibration equipment used at RdF meet the standards of ANSI/NCSL-Z540.1-1994, and all calibrations supplied are traceable to National Institute of Standards and Technologies (NIST). RdF sensors have been qualified on many military and aerospace programs to the environmental requirements of MIL-STD-810. Qualification testing to the requirements contained in RTCA DO-160 has also been done. Test and calibration equipment used at RdF meet the standards of ANSI/NCSL-Z540.1-1994, and all calibrations supplied are traceable to National Institute of Standards and Technologies (NIST).

We meet 10CFR50 Appendix B, CSA-Z299.1 for nuclear programs. We are NUPLC Certified. We meet 10CFR50 Appendix B, CSA-Z299.1 for nuclear programs. We are NUPLC Certified.

RdF Technology, Markets and Specialized Products:

The technologies utilized by RdF for use in its aircraft and aerospace products include fine wire-wound or thin film platimum RTD elements, other wire RTD elements and thermistors. Patented foil and small wire Stikon® surface thermocouples are an RdF exclusive. Complimenting these sensor products are laminated etched foil heaters, Microfoil® heat flux sensors, radiometers/calorimeters, and fine etched foil resistive bridge networks.

The information and photos that follow show basic specifications, physical configurations and applications of RdF sensors. Custom sensors are assigned their own part number identifying the specific sensor characteristics meeting your needs. The information and photos that follow show basic specifications, physical configurations and applications of RdF sensors. Custom sensors are assigned their own part number identifying the specific sensor characteristics meeting your needs.

|

|

Cryogenic

Sensors

A. Cryogenic RTD

B. Hollow Annulus High Pressure LH2 RTD

C. Hollow Annulus LH2 RTD

D. 1/8" Diameter LN2 RTD

RdF’s exclusive hollow annulus elements

combine superior time response, high pressure

capability and ruggedness for cryogen at high

flow rate.

Temperature Range

–286 to 260°C (–450 to 500°F)

Material

Stainless Steel, Inconel

Element

Platinum fine wire:

0.003923 Ω/Ω/°C, required for LH2

0.00385 Ω/Ω/°C, applicable for LN2

Platinum thin film:

0.00385 Ω/Ω/°C, applicable for LN2

Pressure Rating

Up to 20,000 psi

Vibration

>50g, 20 to 2000 Hz

Resistance @ 0°C

100,1000,1380, 2500Ω

Time Constant

<0.5 seconds

|

|

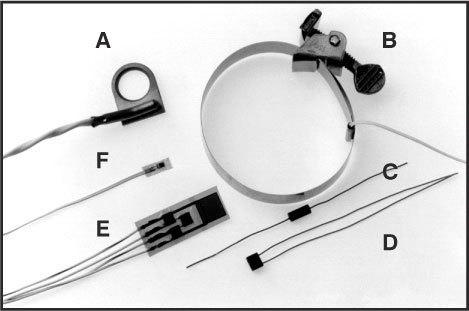

Platinum

Surface Sensors

A. Thin Film Capsule Bolt-on RTD

B. Strap-on Thin Film Capsule RTD

C. Axial Lead Thin Film RTD

D. Thin Film Board Mount RTD

E. REF Grade wire-wound Bridge RTD

F. Thin FIlm Surface RTD

RdF’s unique thin film and flat wire surface

RTD designs employ proprietary processes

to provide sealed, fast, tough, small flexible

sensors to conform to any specified surface

configuration.

Temperature Range

–200 to 340°C (–320 to 645°F)

Material

Kapton® covers

Polyimide laminated

PFA Teflon® fused

FEP Teflon® fused

Element

Platinum thin film:

0.00385 Ω/Ω/°C

Platinum fine wire:

0.003924 Ω/Ω/°C

Vibration

>50g RMS, 20 to 2000 Hz

Resistance @ 0°C

100, 500, 1000, 2000Ω

Time Constant

<0.3 seconds on metal surfaces

|