|

The surface sensor is only able to measure its own temperature and an attempt must be made to make the surface and sensor temperatures the same.

This can be done by placing insulation over the sensor to reduce the effects of the environment and by choosing a mounting method that provides good thermal contact between surface and sensor.

The method chosen for mounting the sensor is equally important.

While good thermal contact is desired, a large mismatch in thermal expansion coefficients may cause strain in a wire Resistance Temperature Detector sensor.

This strain will produce a change in resistance that could be misinterpreted as a temperature change. Most RdF flexible models use miniature supported thin film sensing elements which eliminate strain effects in surface mounted RTDs.

When mounting both resistance and thermocouple sensors, the leads should be in contact with the sensing surface for some length to reduce the effects of thermal conduction from the sensing wire or junction.

As can be seen by this introduction, an accurate surface temperature measurement is not a simple matter.

A review of the application and a procedure for installation should be considered prior to ordering.

It is our intention in these application notes to provide general guide lines for the use of surface sensors.

A. Thermocouple Sensors or RTD Sensors?

A review of the various sensor types and tables of specifications will clearly identify the most significant differences between RTD and Thermocouple sensing types.

In some applications such as those involving temporary, non-critical measurements at medium temperatures, either type would suffice as only cost would be the determining factor.

In general, though, thermocouples have a wider operating range, faster speed of response and are somewhat lower in cost.

RTDs, on the other hand, offer higher accuracy and long term stability.

Should any question of choice arise, the RdF Sales Department will be pleased to offer their recommendations for specific applications.

B. RTD (Resistance Temperature Detectors) Surface Sensors

° Higher Accuracy

° Long Term Stability

° Higher Signal Output

° No Reference Points or Compensation Circuits needed

° –200°C (–320°F) to 480°C (900°F) Operating Temperature

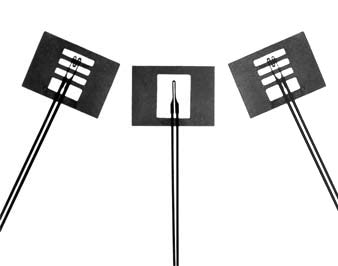

The RTD surface temperature sensors consist of a fine resistance wire or supported thin film sensing grid sandwiched within a wafer-thin insulating carrier and with convenient wire or ribbon lead termination.

Most of these sensors are designed to be cemented in place on the surface to be measured.

However, RdF also offers a silicone rubber overmold version which is usually attached with a band clamp or tape.

RTD sensors, unlike thermocouples, do not require a reference point, ice baths or temperature compensation circuits.

The sensors have a very low thermal mass thereby providing true surface temperature measurements as well as response times as fast as 50 milliseconds. The established position of the platinum sensor as a precision temperature measuring sensor is demonstrated by its selection to define the International Temperature Scale (ITS–90) from –190°C to +660°C. The major reasons for selecting the platinum thermometer as the primary standard are: exceptional stability and repeatability of its resistance temperature parameter.

RTDs have a signal output of 50 to 200 times that of a thermocouple.

This means that temperature measurements can often be made with standard instrumentation. |

C. Thermocouple Surface Sensors

° Very Fast Response

° Wide Operating Range

° Low Cost

° Rugged Construction

° Very Easy to Use

These RdF surface thermocouple sensors are available in wire or foil types.

As the thermocouples are not a resistance device using a grid wire or thin film as in the RTD type surface sensors, they are considerably more rugged for general purpose use and not affected by strain due to mounting materials or methods.

They are inherently simple in design which leads to their lower cost.

All thermocouple surface sensors are characterized by their ability to function at considerably higher temperatures than RTD sensors and their faster time response.

However, the thermocouple sensor generates a low voltage signal which may require accessory amplification which may prove disadvantageous in a high electrical noise environment.

II. Types of Surface Sensors

A. Flexible Platinum Stikon® RTD Sensor

Model 22810

This model is a platinum wire resistance temperature sensor which is designed to be easily installed and can conform to various surface contours.

The standard resistance is 100Ω with a nominal IEC 751 curve (.00385Ω/Ω/°C).

This sensor's useful temperature range is –200°C to +232°C (–320°F to +450°F).

See Data Sheet R-STK

B. Flexible Stikon® Thermocouples

This series of flexible, inexpensive, insulated thermocouples are available in standard type "K", "T", "E", or "J" calibrations.

They are easy to install on various surface contours and are usable from –200°C to +260°C (–320°F to +500°F) continuous and to +371°C (+700°F) for short periods.

Request Data Sheet T-STK |